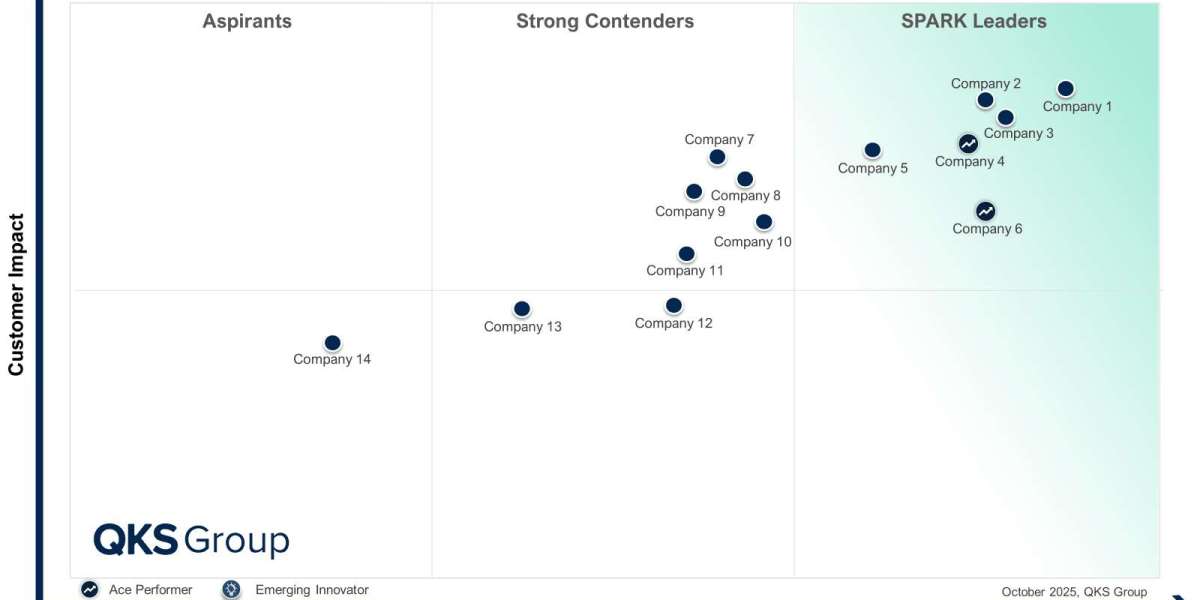

Introduction: Why Smart Manufacturing Matters Today

Manufacturing enterprises are under unprecedented pressure. Volatile supply chains, rising energy costs, labor shortages, sustainability regulations, and increasing customer expectations are converging at once. Incremental automation and isolated digital initiatives are no longer enough to keep pace.

Smart Manufacturing & Industry 4.0 IT Services have become essential for manufacturers seeking to transform operations holistically. These services enable organizations to connect physical assets, operational processes, and enterprise systems into intelligent, data-driven manufacturing environments.

Rather than focusing on individual technologies, enterprises are now prioritizing outcome-focused transformation programs that improve throughput, quality, agility, and resilience—while accelerating time-to-value.

Click Here For More Information: https://qksgroup.com/market-research/spark-matrix-smart-manufacturing-industry-4-0-it-services-large-tier-q4-2025-9921

Market / Industry Overview

Smart Manufacturing & Industry 4.0 IT Services represent a comprehensive services-led approach to industrial digitalization. The domain spans consulting, system integration, and managed services that collectively modernize manufacturing value chains.

Key service components include:

- Digital strategy and Industry 4.0 roadmap consulting

- OT/IT integration across MOM/MES, PLM, ERP, SCADA, and control systems

- IIoT platforms, edge computing, and real-time data pipelines

- Data ingestion, validation, contextualization, and analytics architectures

- Digital twin and digital thread implementations

- Private 5G and advanced industrial networking

- Managed cybersecurity, cloud-edge operations, and lifecycle services

From a business perspective, these services are no longer discretionary. Manufacturers are investing to improve asset utilization, reduce downtime, enhance product quality, and build resilient operations that can adapt quickly to disruption.

Industry advisory firms such as QKS Group increasingly emphasize that success in Industry 4.0 depends less on tools and more on the ability to orchestrate technologies into scalable, enterprise-wide programs

Key Challenges Businesses Face

Despite growing investment, many organizations struggle to realize consistent returns from Industry 4.0 initiatives. Common challenges include:

- Fragmented IT and OT landscapes with limited interoperability

- Legacy MES, PLC, and automation systems that are costly to modernize

- Poor data quality and lack of contextualized operational insights

- Cybersecurity risks introduced by increased connectivity

- Difficulty scaling pilots across plants and geographies

- Shortage of skills in industrial data engineering, AI, and cloud-edge operations

Without a unified service framework, digital initiatives often remain siloed—delivering localized improvements rather than enterprise-level impact.

Key Trends & Innovations Shaping the Market

Several technology and service trends are accelerating the adoption of Industry 4.0 services:

Industrial AI and Advanced Analytics

Machine learning, predictive analytics, and computer vision are being embedded into manufacturing execution, quality inspection, and maintenance workflows. These capabilities enable proactive decision-making and autonomous optimization.

Cloud–Edge Convergence

Manufacturers are adopting hybrid architectures that combine low-latency edge processing with cloud-based analytics, AI model training, and enterprise integration.

Digital Twin and Digital Thread Expansion

Digital twins are evolving from design tools into operational assets that mirror real-time factory behavior. Digital threads connect engineering, production, quality, and service data across the lifecycle.

Private 5G and High-Performance Connectivity

Private 5G networks are enabling reliable, low-latency communication for robotics, AGVs, AR/VR, and remote operations in industrial environments.

Managed, Outcome-Based Services

Service providers are shifting toward KPI-aligned managed services, focusing on uptime, throughput, quality, and energy efficiency rather than one-time deployments.

Together, these trends reinforce the strategic role of Smart Manufacturing & Industry 4.0 IT Services as long-term transformation enablers.

Benefits & Business Impact

When implemented effectively, these services deliver measurable business value:

- Operational efficiency through real-time visibility and predictive control

- Improved product quality via closed-loop quality management

- Reduced downtime through predictive and condition-based maintenance

- Faster time-to-market enabled by connected engineering and production systems

- Scalable operations across multi-site and global manufacturing networks

- Enhanced cybersecurity for converged IT/OT environments

- Sustainability improvements through energy optimization and emissions monitoring

The ROI extends beyond cost savings. Manufacturers gain agility, resilience, and the ability to respond rapidly to market and supply chain changes.

Use Cases and Real-World Examples

Common enterprise use cases include:

- Connected factories with unified MES, IIoT, and analytics platforms

- Predictive maintenance programs reducing unplanned downtime by 20–40%

- Digital twins of production lines used to simulate throughput and changeovers

- Vision AI-based quality inspection integrated with MES and PLM

- Private 5G-enabled plants supporting autonomous logistics and robotics

- Cyber-resilient manufacturing environments with continuous monitoring

These examples demonstrate how Smart Manufacturing & Industry 4.0 IT Services translate advanced technologies into operational outcomes.

Download Sample Report Here: https://qksgroup.com/download-sample-form/spark-matrix-smart-manufacturing-industry-4-0-it-services-large-tier-q4-2025-9921

How Organizations Can Choose the Right Solution

Selecting the right service partner is critical to success. Decision-makers should evaluate providers based on:

- Proven experience across both IT and OT domains

- Deep manufacturing and industry-specific expertise

- Strong ecosystem partnerships with automation and platform vendors

- Scalable reference architectures rather than bespoke point solutions

- Robust cybersecurity and compliance capabilities

- Ability to deliver managed, outcome-driven engagements

Organizations should prioritize partners that align transformation initiatives with business KPIs such as OEE, yield, energy efficiency, and time-to-market.

Future Outlook (2025–2028)

Between 2025 and 2028, the market will continue to mature rapidly:

- Industry 4.0 initiatives will move from pilots to standardized enterprise platforms

- AI copilots will support operators, engineers, and plant managers

- Digital twins will extend across supply chains and product ecosystems

- Sustainability metrics will be embedded into core manufacturing systems

- Managed services will dominate as manufacturers seek predictable outcomes

Smart manufacturing will increasingly define competitive differentiation in global industrial markets.

Connect with our analyst: https://qksgroup.com/analyst-briefing?id=9921

Conclusion

Smart manufacturing is no longer a future ambition—it is a present-day imperative. By combining strategic consulting, deep OT/IT integration, advanced analytics, and managed services, Smart Manufacturing & Industry 4.0 IT Services enable manufacturers to modernize operations with confidence and speed.

For technology buyers and enterprise leaders, the opportunity lies in moving beyond fragmented digital initiatives toward unified, outcome-led transformation programs that deliver sustainable business value.